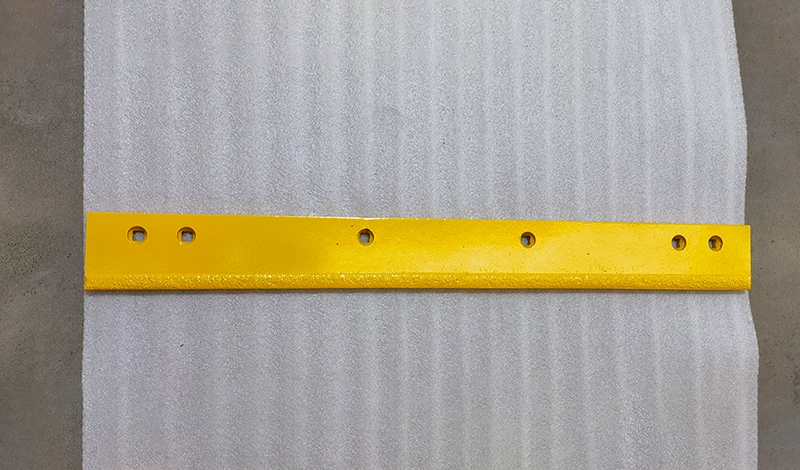

SCT’s carbide snow plow blades have excellent wear resistance and service life, and have excellent test results in most operating environments.

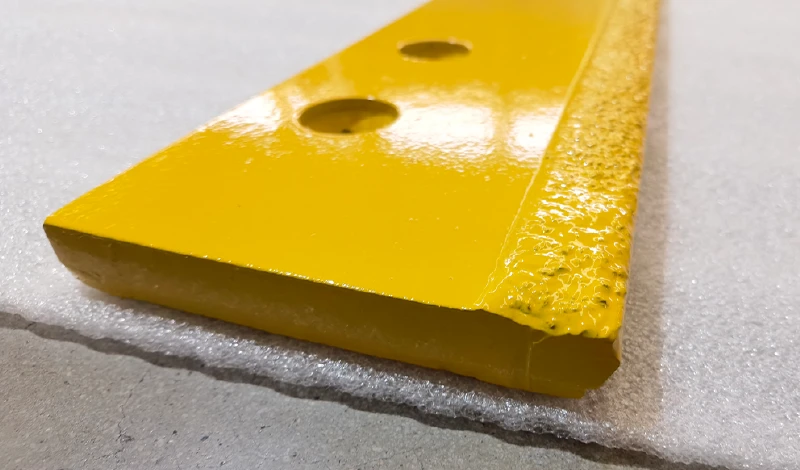

The standard is a flat, 3/4″ thick metal blade with a single carbide insert brazed onto the face. The carbide provides an excellent balance of abrasion resistance and impact protection that cuts ice and compacted snow on the first pass.

gallery

Technical Parameters

Carbide snow plow blades can be mounted on the front, underbody, and wing of a snow plow according to different applications. Though carbide cutting edges look similar to traditional steel cutting edges, there are tungsten carbide inserts that are brazed into milled grooves of the steel blade or overlayed on the surface, greatly increasing the service life of snow plow blades and minimizing downtime.

Compared to carbide snow plow cutting edges, standard steel cutting edges are easily worn out which will result in frequent blade changes and need more maintenance. However, tungsten carbide is an extremely tough and durable cutting edge material that extends snow plow blade life up to 10 to 20 times over traditional steel blades. Besides, carbide snow plow blades have excellent wear and impact resistance and outstanding cutting performance.

SCT is proud of its carbide snow plow blades made from micro-grain tungsten carbide and premium C45 steel. We supply a full selection of carbide cutting edges in varied sizes and custom blades are also available.

What materials are JOMA Style Blades made of?

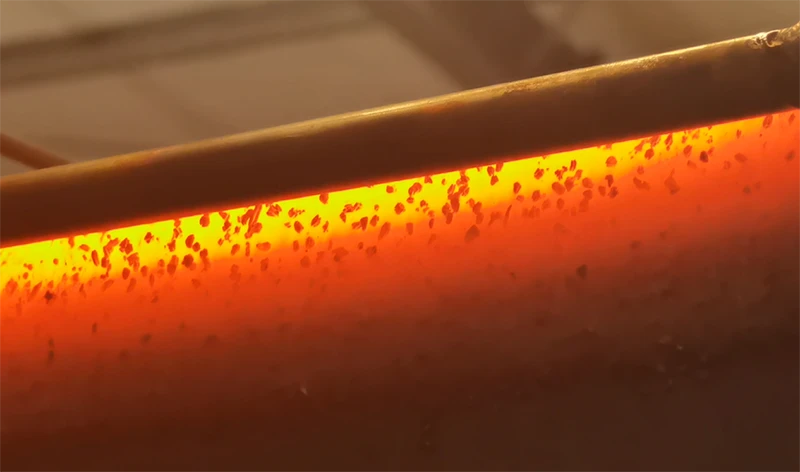

Factory-produced tungsten carbide inserts are brazed together with steel segments, then coated with ultra-low-temperature-resistant rubber.

SCT oversees every step of the process, ensuring consistent quality and traceability of every batch of materials.

Can l customize the blade design or packaging?

Of course, in addition to standard plow blade or carbide inserts sizes, you can discuss other sizes with us to meet your specific requirements.

Packaging can be tailored to your specifications, including neutral packaging, fumigation-free wooden crates, and pallet packaging. We always adhere to your requirements.

What applications are these blades suitable for?

It can adapt to almost any working environment conditions:

motorwary, national & regional roads; local roads; urban areas; airports; parking lots...

Joma-style blade will reduce the damage to highway lane markings. Unlike a rigid steel blade, the Joma-style will form to the contour of the road. In doing so it cleans the road surface more effectively and therefore may require less salt or sand to be applied.

What is the minimum order quantity (MOQ)?

To minimize shipping costs, we recommend purchasing a minimum of 500 snow plow blades.

We ensure that each batch of snow plow blades and carbide inserts undergoes rigorous quality inspection and performance testing before delivery.

How do you ensure product quality?

SCT independently completes all production processes, from raw material powder to finished blades. We conduct dedicated quality inspections at the end of each process, and rigorously test the finished product for both quality and performance.

We are always willing to provide samples for testing and issue factory quality inspection reports to our first-time customers.