Senthai Cemented Carbide Tools (Thailand) Co., Ltd.

Welcome to SENTHAI, we are a US-invested snow plow blade and road maintenance wear parts manufacturer located in Rayong, Thailand.

We have a group of core Thai technicians and a management team with decades of production experience. We have more than ten inventions and utility patents in production, and have ISO9001, ISO14001 and other international certifications. In the production of snow plow blades, we have provided North American snow removal equipment manufacturers and the snow removal market with products with excellent cost performance and stable performance for many years with our unique production technology and cost control.

Our new snow plow blade production base in Rayong is under construction and is expected to be put into production in the fourth quarter of 2025.

Carbide wear parts production experience

Various Types of Blades

Deep partnership

Automated production line factory

Our Factory

As a leading manufacturer in the snow plow blade manufacturing industry, we have a working environment and production line layout that all our partners praise.

A tidy workshop is conducive to our product quality control, which is also a reflection of our high manufacturing level.

WET GRINDING WORKSHOP

operates 8 sets of 300-type ball mills 24/7.Through careful material ratio adjustments,we create raw materials with diverse physical properties for customized blends.Additionally,our meticulous attention to maintaining a dust-free environment guarantees the purity and absence of impurities in our raw materials.

THE PRESSING WORKSHOP

utilizes the combination of robotic arms and automated pressing systems to ensure the precision and consistency of every pressing operation,thereby significantly enhancing both the production efficiency and stability of our products.With a maximum punching capacity of 500 tons,our operations guarantee uniform s stress distribution and excellent forming precision.

SINTERING HALL

is equipped with cutting-edge heat treatment equipment,including vacuum and low pressure furnaces,as well as specialized facilities for partial pressure sintering,quenching,and cryogenic treatments.These advanced technologies guarantee the exceptional quality and stability of our cemented carbide production.

FACTORY HALL

We always maintain the highest standards of on-site management and a clean and tidy workshop environment to minimize the level of impurities in the products. This is our determination to quality, which is rare in the tungsten carbide manufacturing industry.

WELDING HALL

employs automated induction welding for efficient and high-quality joining of snow plow inserts with the embedded steel plate.This advanced technique ensures uniform temperature distribution and enhances the bond strength between the cemented carbide and the steel plate.A subsequent annealing process further enhances tool toughness.

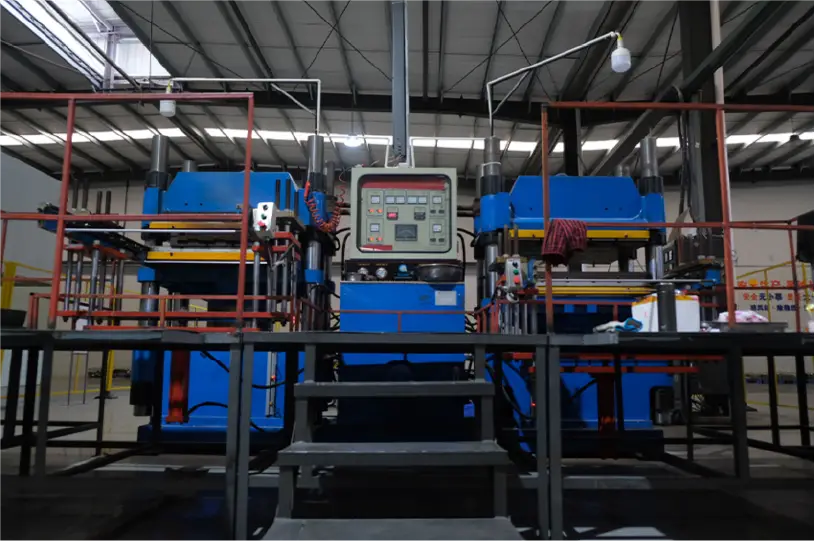

THE VULCANIZATION WORKSHOP

applies a durable,low-temperature resistant rubber layer to the surface of the snow shovel blade.This vulcanized rubber layer enhances wear resistance,protects the steel plate,and extends the tool’s service life by reducing impact and improving low-temperature and corrosion resistance.

100% MANUFACTURED IN THAILAND

From our state-of-the-art headquarters to our advanced manufacturing facilities, we combine innovation, quality, and craftsmanship to deliver reliable performance in every product.

Our Headquarters is Located in Rayong, Thailand

Rayong is a rapidly developing industrial hub in eastern Thailand, known for its strategic location and advanced infrastructure. Our decision to base our headquarters here is rooted in long-term vision and operational efficiency.

From this central location, we manage our core operations, including R&D, engineering, quality control, logistics coordination, and global customer support. Rayong provides the ideal environment for streamlined production and international connectivity.

100% Manufactured and Assembled in Thailand

Every product we deliver is conceived, manufactured and assembled under the supervision of our local production management team in Thailand.

By keeping the entire value chain—from initial design to final packaging—within Thailand, we are able to:

Maintain full control over product quality and consistency

Shorten development and delivery cycles

Respond to customer needs quickly with rich experience

Ensure compliance with global manufacturing and environmental standards

STRICT QUALITY CONTROL PROCESS

From raw material procurement to final packaging and shipment, we have multiple quality control measures in place, including but not limited to:

Raw material inspection upon arrival:

Ensuring that basic materials meet standards.

Process quality control:

Automated inspection equipment is installed at key stages of the process.

Final product sampling inspection:Raw material inspection upon arrival:

Functional and appearance tests are conducted on a proportional basis.

Pre-packaging review:

Ensuring that products are complete and free of defects.

.webp)

.webp)